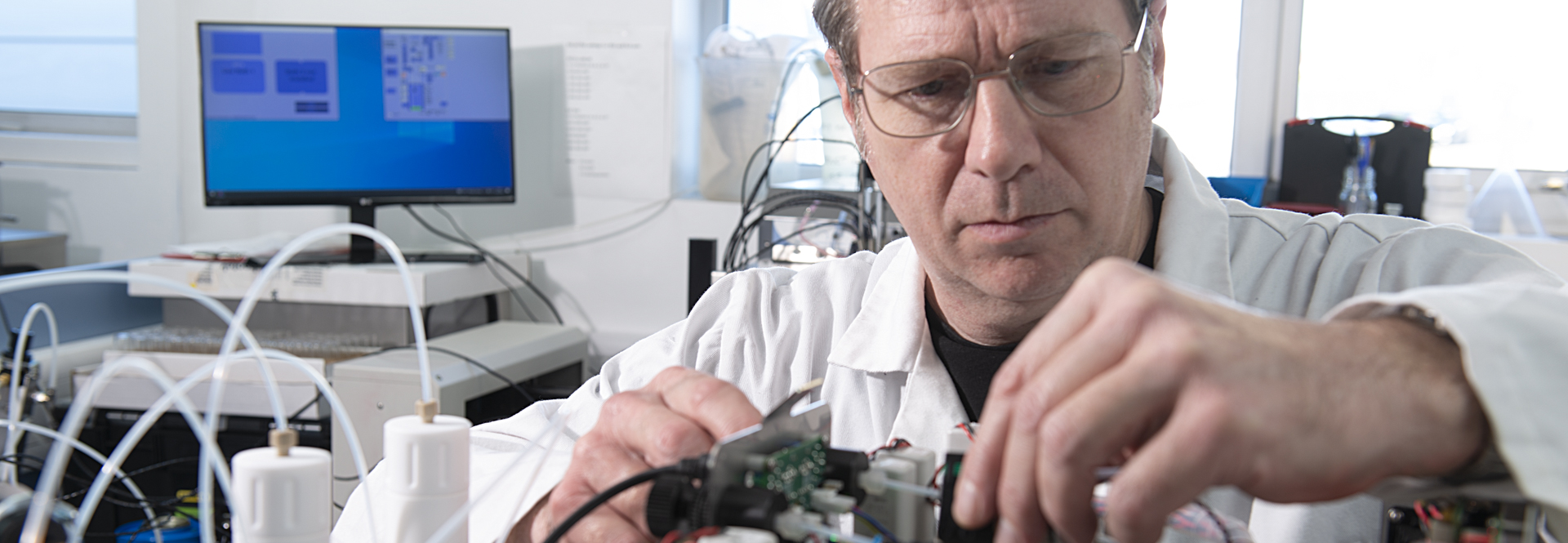

Our field service engineers are on hand to come to your laboratory. Service includes scheduled preventative maintenance or breakdown visits. PSL Rheotek USA Inc offers on-site service support across North America and Mexico. Key spare parts are stocked in the US for overnight dispatch. Other parts are usually on a 1–2-week lead time from the factory in the United Kingdom.

ON SITE SUPPORT

We come to you

Regular maintenance

Service Contracts are available that guarantee at least one annual visit for preventative maintenance. This ensures your polymer viscometer’s continuous, market-leading performance.

Continuous supply

Key spare parts are available for overnight dispatch. Weekly shipments from the factory in the United Kingdom to PSL Rheotek USA Inc ensure a continuous supply of needed parts.

In house expertise

As a PSL Rheotek Polymer Viscometer owner, you have access to PSL Rheotek’s in-house expertise, with upgrades and modifications to existing instruments available.

Our team

Holly Osowski

Office Manager

Holly’s contributions to PSL Rheotek USA include her efficient organizational, administrative, and accounting abilities and her high spirits. She brings joy and collaboration to our organization and, with her experience and knowledge, is always there for the customer. Holly is your point of contact for spare parts.

Mark Stevens

Sales/Service Engineer

Mark Stevens is the epitome of reliability. As the backbone of PSL Rheotek USA, Inc., his commitment to customers is unmatched. His profound understanding of our products and his composed demeanor ensure customers have an excellent experience, from the sales process to support.

Greg Lazarczyk

Operations Director

Greg is a solutions man. His breadth of knowledge in many areas allows him to see obstacles as stepping stones and create new paths forward for customers, employees, and the business alike. His 40+ years of experience, generosity of spirit, and focus on the future make him an exemplary leader.

About the PSL Rheotek RPV Polymer Viscometer

Market leading automation for IV, Viscosity Number, Relative Viscosity & almost any other test protocol from the world of dilute solution polymer viscosity. In many process plant laboratories, the “Rheotek” is the trusted partner for this tricky yet important test.

The original PSL Rheotek Polymer viscometer was developed in partnership with US industry laboratories towards the end of the 1990’ies. This happened in response to an industry demand for automation of this crucial quality test on the product stream.

As an established manufacturer of prime capillary viscometers for industry laboratories worldwide, this was a natural progression for PSL Rheotek. All the glass viscometers used in the automated polymer viscometers are manufactured in-house by our Master Glassblowers. Calibration follows in our ISO 17025 accredited laboratory on site.

Detection technology, cleaning protocol, and user interface were designed with the polymer industry’s demands in mind. The work was always focused on the challenges of molecular-level testing with full method compliance. The priorities of Certificate of Analysis testing were our sole focus.

We proudly claim full method compliance. Get in touch to arrange a meeting to ask how we do it.

Questions may arise once the instrument has been installed, commissioned, and is in operation. We have gathered a few common questions from instrument owners below.

FAQ

Frequently Asked Questions

How often should the RPV polymer viscometer be calibrated?

Running a reference sample at regular intervals best ensures ongoing quality assurance of the automated viscometer’s performance. If an in-house reference sample is not available, we can purchase one. We hold an extensive catalog of reference samples covering a wide variety of polymers.

How often should we run the blank solvent/t0?

In some cases, the blank or solvent value is determined at the beginning of every day. At the other end of the spectrum, we have clients who only measure their blank values once or twice per year. It is recommended that the interval be stipulated in the laboratory quality manual. We will be pleased to assist you in determining a robust interval for your polymer application.

How many milliliters of sample are required?

The standard AKV Ubbelohde viscometer tube requires 12-17 mL of sample. When the sample has been charged into the viscometer tube, the meniscus must reach the lower filling line. The tube is visible through the window at the front of the viscometer bath.

How often do we need to replace the glass viscometer?

If the viscometer is working to specification, there is no need to change the glass viscometer. However, with some applications, a very slight residue may build up on the inside of the viscometer over time. This can be resolved by carrying out an acid-cleaning procedure. If this is not an option, the alternative is to replace the viscometer. If the viscometer is damaged, it should be replaced.