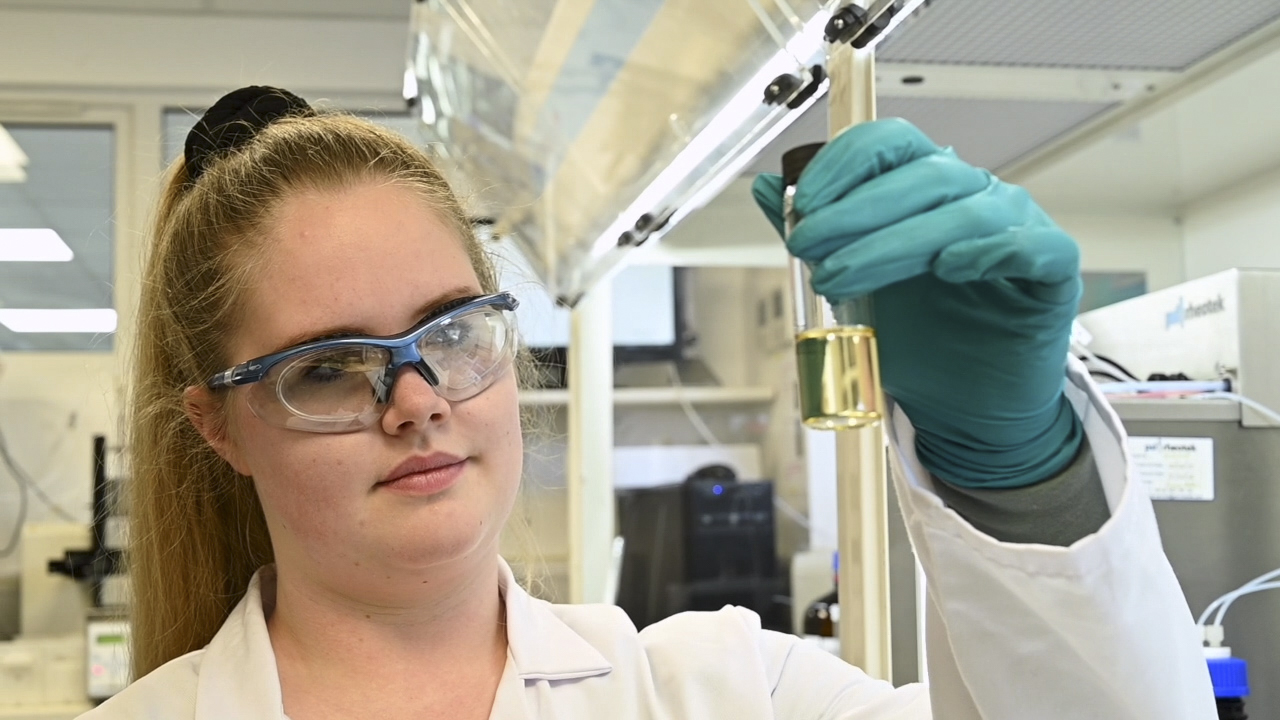

CATEGORY BENEFITS

Why quality matters in glassblowing

Flow properties are dictated by the smoothness of the inside surface of the viscometer. A glass capillary viscometer is a precision instrument. Any irregularity can cause turbulence in the sample and unpredictable behaviour. For repeatable measurements and the most regular flow, a smooth surface is needed.

Perfect smoothness

The most important feature of quality viscometer is the smoothness of the inside surface. The properties of the inside surface of the viscometer determine the flow of the sample. A smooth surface with a soft curve leading from the viscometer tube into the capillary section provides ideal conditions for the undisturbed flow of the sample.

Best flow properties

Any irregularities in the interior surface of the glass may cause turbulence in the sample movement leading to irregular flow time determinations. This will show up as a difference between the first and the second flow time when measuring viscosity. For the best chance of getting the second flow time to agree, choose a PSL Rheotek Viscometer to measure viscosity.

Quality materials

All PSL Rheotek Capillary Viscometers are made from low thermal expansion borosilicate glass tubing.

Made in the UK

We have a complete in-house production capacity for all our products in United Kingdom We serve laboratories all over the world from our facility in Essex.

Measuring Different Liquids

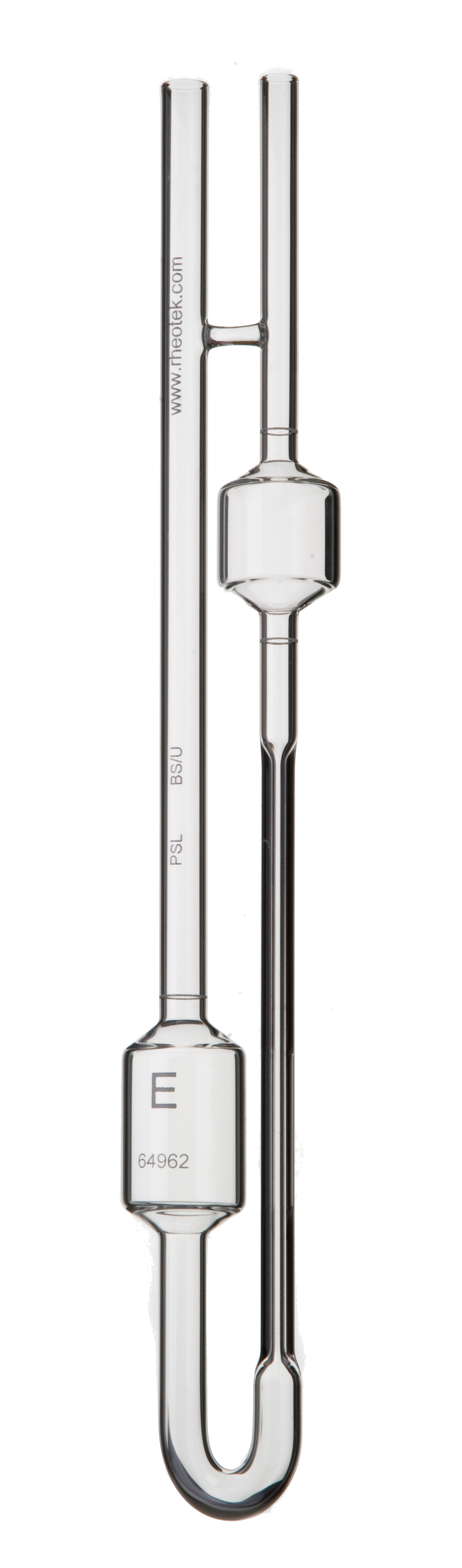

For measuring transparent liquids, we recommend the ASTM Ubbelohde viscometer. The constant of this viscometer is temperature independent. Designed with an air arm, the ASTM Ubbelohde Viscometers return accurate results using an approximate quantity of sample. For measuring opaque liquids, we recommend the U-Tube reverse flow viscometer.

Certified at the highest level

All glass viscometers from PSL Rheotek are supplied complete with a UKAS (ISO 17025) Certificate of calibration, laboratory No. 0247. All certificates are fully traceable to the Master Viscometer Scale held at PSL Rheotek. All viscometers are calibrated directly against Master References in the on-site laboratory.

PRODUCT GALLERY

High performance glass viscometers

FAQ

You asked, we answered

How do you use a glass capillary viscometer?

You use a stopwatch to time the meniscus of the sample as it passes the timing lines. The sample flows under gravity.

What equipment do you need to use a capillary viscometer?

The viscometer itself, a viscometer holder for the viscometer, a constant temperature viscometer bath and a stopwatch. Depending on the type of glass viscometer, other accessories such as silicone tubing, a clamp, a stopper and a disposable syringe may also be required. For beginners, we supply ready packed viscometer operating kits for the different types of tubes.

Why do I need a constant temperature viscometer bath?

Kinematic viscosity and temperature are usually inter-linked. Viscosity decreases, when temperatue increases. A viscosity result is reported at a specific reference temperature. The most common reference temperature for kinematic viscosity is 40 degrees C.

What if I just measure the sample at room temperature?

Then the result will represent only an approximation. At room temperature, it is unlikely that repeatable flow times will be achieved.

Do I need to use a thermometer?

Yes, a liquid in glass or digital thermometer is essential to verify the bath temperature. The thermometer should conform to the specifications set out in a test method (e.g. ASTM D445, IP71, ISO3104) and be calibrated e.g. by an ISO 17025 laboratory.

Why do I need a chiller for the bath, when running it at 25 degrees C?

The tolerance band for temperature stability is typically +/- 0.02 degrees C. To achieve this level of temperature stability, the bath heaters are not sufficient when the test temperature is close to ambient. Even with modern high tech heaters, there will be temperature spikes, which exceed +/- 0.02 degrees C. Applying external cooling will counter these temperature spikes.

Why should I buy a PSL Rheotek branded viscometer?

The flow properties of the viscometer are determined by the interior surface of the glass. This should also be as smooth as possible in order to allow the sample to flow with the minimum of turbulence. Look out for smooth transitions between the different parts of the viscometer tube, when trying to assess the quality of a viscometer tube. At Poulten Selfe & Lee Limited, we take pride in manufacturing viscometers with superior flow properties.

I want to save money, can you sell me an uncalibrated viscometer?

Yes, we can. However, you will need to perform a calibration yourself, before you can use the viscometer tube. To perform the calibration, you will need to buy two viscosity reference standards from us and then conduct the calibration procedure as described in ASTM D446 or ISO 3105. Our preference is to sell you a capillary viscometer complete with an ISO 17025 certificate of calibration. This certificate will state the serial number of your tube as well as the viscometer constant of that specific tube to 4 significant figures. The calibrated viscometer is ready to use out of the box.

We have an audit coming up and have lost our calibration certificates, can you send us a replacement certificate?

Please contact us wia the contact form and provide us the serial number and the type of viscometer for possible reissue of certificates. If it is possible to reissue the certificate, we will send the replacement within 1-2 days. This service is chargeable.

How long is the calibration of the viscometer valid for?

There is no universal recalibration interval for glass viscometers. Our recommendation is for users to validate the calibration constant by running a viscosity reference standard in the tube as and when Quality Control of the measurement is required. See here to find the appropriate standard. If in doubt about the correct standard to use for this purpose, please feel free to contact us.

CUSTOM SOLUTIONS

Searching for custom instrumentation for your unique requirements?

Each PSL Rheotek viscometer system is configured for the owner! A wide variety of international test method protocols are readily available in the software and company specific method protocols are also supported.