QUALITY IS EVERYTHING

IV, Viscosity Number & K-Value from the US market leaders in polymer viscosity

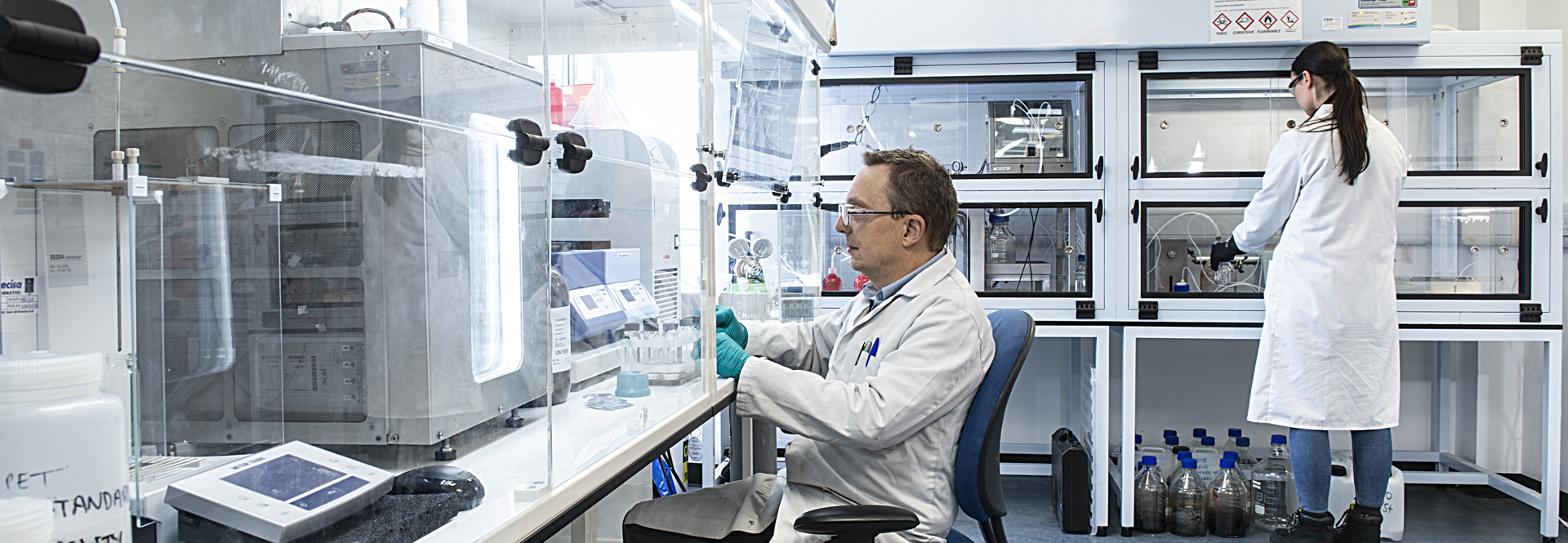

Certificate of Analysis testing and ongoing QC test work to the highest standards. PSL Rheotek USA Inc. delivers the complete solution. Leading supplier of instrumentation for IV of PET and Viscosity Number of Polyamide.

Process plants, recyclers, compounders and polymer institutes across the USA rely on their PSL Rheotek Polymer viscometer. Instrument owners benefit from strict method compliance in a modern technology package.

The raw material must be the right grade for each industrial process. PSL-Rheotek RPV Polymer Viscometers provide reliable, certified data to the manufacturer, the seller, and the buyer.

At PSL Rheotek USA Inc. we focus on designing the right configuration of instrumentation for each client. Our mission is to help manufacturers obtain the right data in the easiest and most convenient way using glass capillary viscosity measurements.

With roots dating back to 1850, PSL Rheotek USA Inc. draws on a wealth of expertise and experience. The glassblowing standard is second to none. We make beautiful viscometers with excellent flow properties.

The glass viscometers are installed in a modern technology package for automated operation, calculation of results and cleaning. Our mission is to provide the most repeatable data with minimal operator intervenion.

173

years of experience

200+

viscometers sold

57

countries served

1300+

satisfied clients

THE ORIGINAL METHOD

Dilute solution viscosity is the leading method used for gaining consistent data on the molecular weight of polymers.

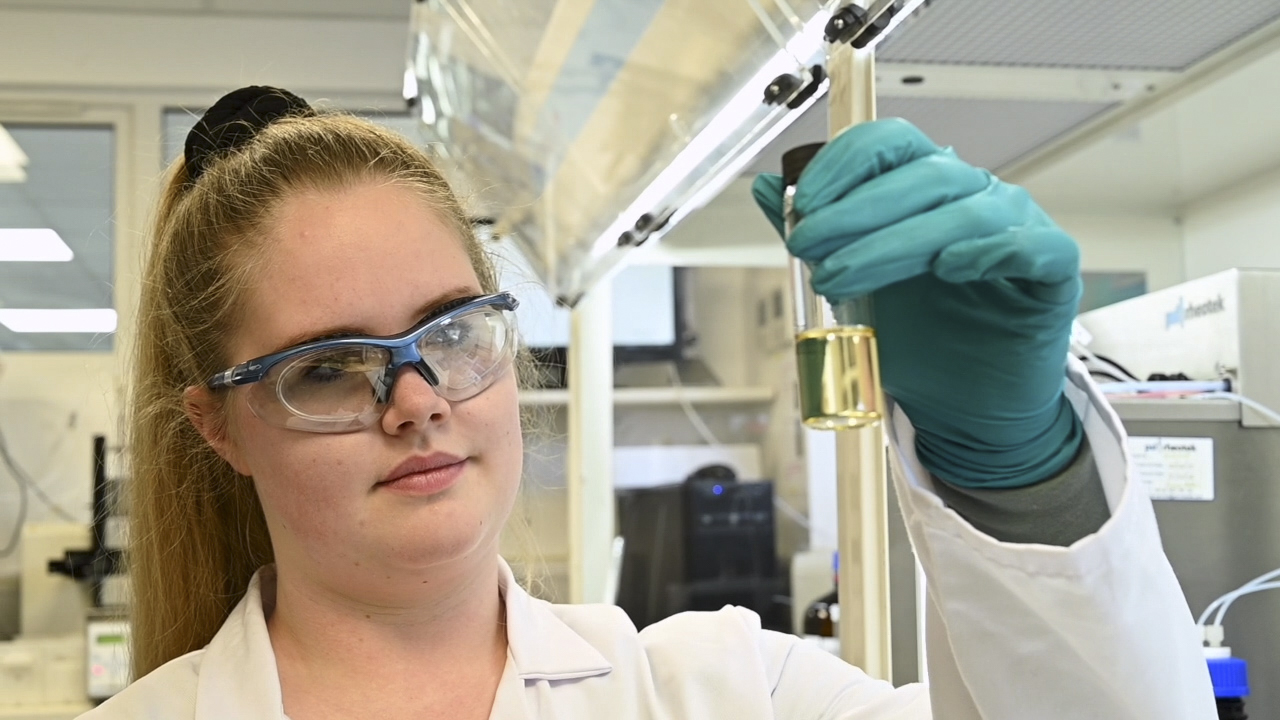

Only the glass viscometer method provides the real data for solution viscosity. Solution viscosity is determined by recording capillary viscometer flow times in a temperature-controlled liquid bath. Doing this by hand is time-consuming, exposes the operator to hazardous chemicals, and can easily go awry.

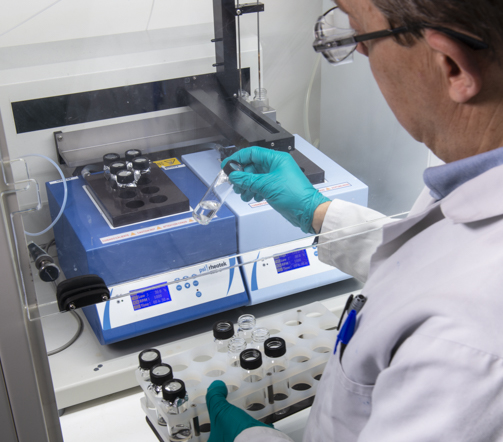

The RPV Polymer Viscometer automates old-school wet chemistry and removes the hassle and hazards while strictly adhering to test method protocol.

PRINCIPLE OF MEASUREMENT

Dilute Solution Polymer Viscometry with Capillary Method

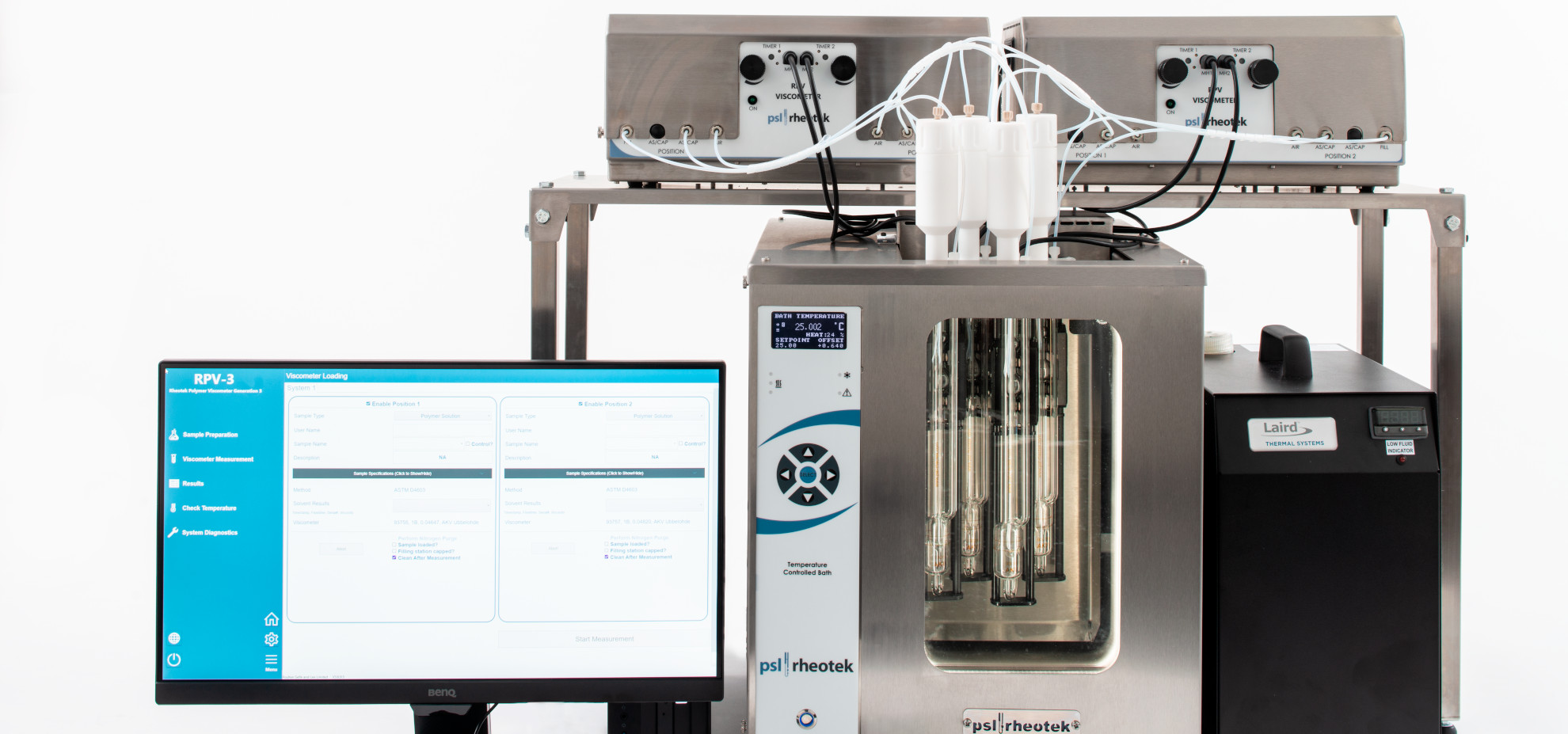

The pure solvent is dispensed into the capillary viscometer and measured. The second step is to enter a solvent with a small amount of fully dissolved polymer. The dilute polymer solution will have a slightly higher viscosity than the pure solvent.

The increase in kinematic viscosity caused by the presence of free-flowing polymer molecules is the basis of dilute solution polymer viscometry. This physical measurement allows process labs to report viscosity number, reduced viscosity, intrinsic viscosity, and other units as specified in international test methods.

MOLECULAR LEVEL TEST WORK

Accurate Solution Viscosity Testing with PSL Rheotek RPV Viscometer

Solution viscosity is a molecular-level test involving wet chemistry. The PSL-Rheotek RPV Polymer Viscometer brings accurate molecular-level testing within reach of the plant laboratory. Precision engineering allows this mechanical piece of equipment to conduct the test to the highest standards.

Test methods for solution viscosity stipulate the use of a calibrated glass capillary viscometer. The glass viscometer must be fitted in a stirred liquid bath for temperature control, which is the most accurate method for determining viscosity.

YOUR TRUSTED PARTER

Accurate Data Demands Real Work

PSL Rheotek USA Inc. is the leading US supplier for:

– Viscosity Number of Nylon, ASTM D789 and ISO 307

– IV of PET, ASTM D4603

– IV instruments for polymer testing

– Custom requirements in the polymer viscosity field

For full compliance with ASTM choose the PSL Rheotek RPV Polymer Viscometer

– Automated measurement in capillary viscometer

– Fully traceable data

– Transparent software allows for easy troubleshooting

– IV of PET testing for Certificate of analysis and process control

– 25 years on the market in North America. Leading supplier to process industry laboratories

Your go-to partner in North America for solution viscosity since the late 1990’s

– Full client discretion guaranteed

– Expedient processing of NDAs

PSL Rheotek USA Inc

Sales and Service Support in USA