Polymer Testing

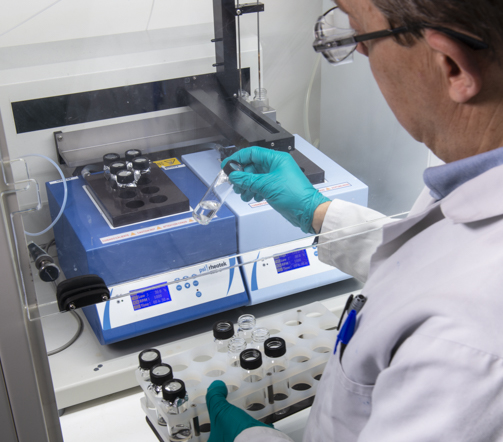

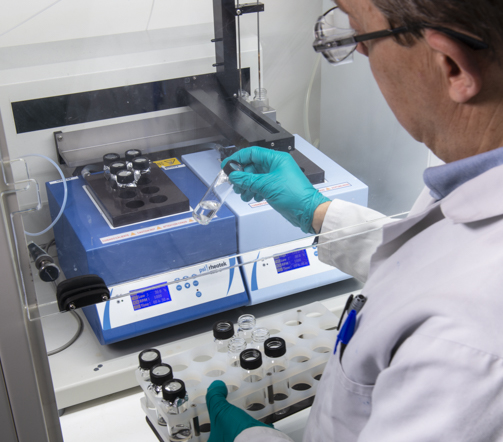

Enjoy the benefits of working with the capillary viscosity experts for solvent based viscosity. Polymer and pulp testing carried out in-house on behalf of customers. Send your dilute solution viscosity samples to us for test method compliant measurement. Polymer viscosity data correlates with molecular weight. Recycled, compounded and virgin material welcome.

TRACEABILITY & ECONOMY

Recalibration of viscometers

Viscometers are returned to clients with an ISO 17025 certificate of calibration. Details on the scope of calibration services available on the UKAS website under Laboratory No. 0247. All certificates of calibration issued by the PSL Laboratory for recalibrated viscometers are issued under our ISO 17025 accreditation. The data is fully traceable to the primary reference for viscosity. There is no need to buy replacement viscometers to satisfy an audit requirement, a a recalibrated viscometer can be as good as new. Plus, we can also repair your damaged viscometer.

Measuring Viscosity

Viscosity is a measure of a fluid’s resistance to flow, and it is an important property in various industries such as petroleum, pharmaceuticals and food processing. The basic principle behind capillary viscometry involves measuring the time it takes for a fluid to flow through a narrow capillary tube under gravity or an applied force. Measuring Viscosity by this method is the main reference method across the world.

Viscosity Testing

IV of PET, K-Value of PVC, viscosity testing of PP/PE. PSL Rheotek is your dedicated partner, offering state-of-the-art technology and expertise in solution viscosity testing. Send your samples to our laboratory in Essex, United Kingdom. Small and large batches welcome.