WHAT IS A CAPILLARY VISCOMETER?

Simple principle

The use of a glass viscometer is often perceived to be complicated and challenging. With the right viscometer for the job in hand, it does not have to be like that. In fact, the principle of the glass viscometer method is extremely simple. The kinematic viscosity of the sample is determined by recording the time it takes for the meniscus of the sample to pass between two timing lines.

Different sizes

The precision bore or capillary section of the viscometer has a specific inside diameter, which corresponds to a given size of viscometer. For samples, which appear to be “thick” or have a high viscosity, the diameter will be relatively large. For samples with a low viscosity, the appropriate capillary section has a narrower inside diameter. Guidelines for operating a glass viscometer typically instruct users to choose a size, which will return a flow time of 200 seconds or more. Details of diameters and sizes are given in international specifications agreed by industry world-wide. The most used specifications for glass viscometers in North America and Western Europe can be found in ASTM D446 and ISO 3104.

Viscosity matters

Glass viscometers are mainly used for measuring the kinematic viscosity of oils and polymers. The viscosity data obtained from measuring a specific product often form part of the specification of the product in question. Engine oil for a vehicle is an example of this. It must be viscous enough or “thick” enough to provide lubrication when the engine is hot. On the other hand, it also must be “thin” enough to provide efficient lubrication to a cold engine.

Agreement on product specification

Another important field, where kinematic viscometry is used, is in the world-wide trading of marine fuel oil. When a cargo vessel bunkers fuel oil to go to China, both seller and buyer of the tanker-load will typically book an independent testing laboratory to test the viscosity of load as well as other parameters. The capillary viscometer method measurements are relatively easy to replicate anywhere in the world using a constant temperature bath, a calibrated glass viscometer and a stopwatch.

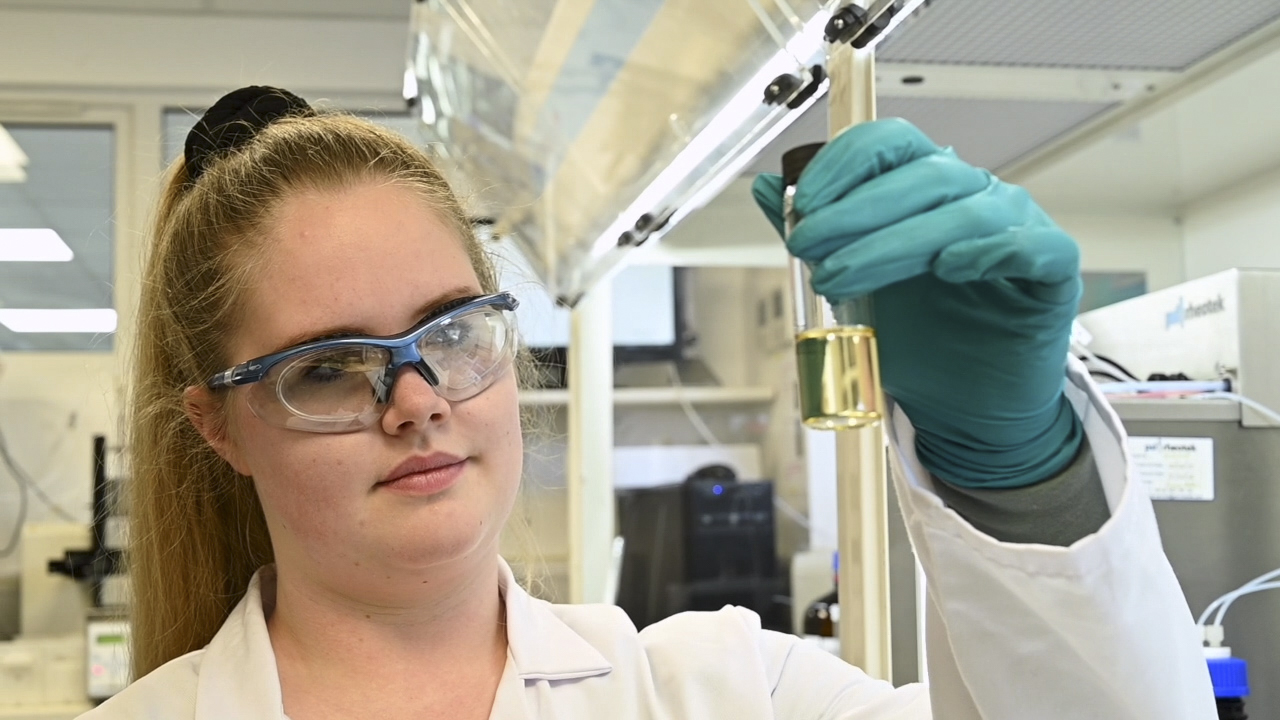

How to use a glass viscometer

When the meniscus passes the first timing line, the operator activates a calibrated stopwatch. At the second line, the stopwatch is used again. The process requires full focus and good hand to eye coordination.

This will only work well when the glass viscometer is held at a stable temperature. All viscometer measurements require accurate temperature control. This is usually achieved by fitting the viscometer tube in a constant temperature bath.

Approximate sample volume

Transparent samples can be measured in viscometers of the suspended-level type. These viscometers are called Suspended-Level, Ubbelohde, Miniature Suspended-Level or Suspended-Level Shortened Form. The classification of “suspended-level” refers to the method of operation.

Suspended-Level viscometers are built with a fill arm, a capillary arm and an air arm. The air arm is open to atmosphere and the viscometer will return an accurate result without requiring a tightly controlled sample volume.

Direct flow viscometers with two arms

The other category of glass viscometers for transparent samples are known as direct flow viscometers. These viscometers have only a capillary arm and a fill arm. For the result to be accurate, the sample volume must be controlled very tightly. This requires a higher level of skill from the operator, than the suspended-level type of viscometer. Popular designs include Cannon-Fenske Routine, BSU-Tube etc.

Reverse flow viscometers are for opaque samples

If the sample in question is opaque, it will be necessary to use a viscometer, which is specifically designed for this purpose. These viscometers are often described as reverse flow viscometers. Designs include BSU-Tube Reverse Flow, Cannon-Fenske Opaque, Zeitfuchs Cross Arm and more.

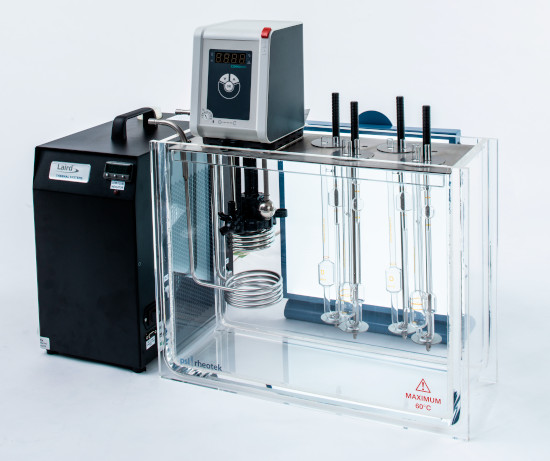

Viscometer baths

To use a capillary viscometer correctly, the test method requirement for temperature stability is typically +/- 0.02 degrees C. To achieve this stability, precision instrumentation is required. At tempereatures near and below ambient, the bath needs both heating and cooling. Viscometer baths are available in different sizes and different designs according to the intended temperature of measurement.

Sample types

- Diesel or gasoil at 40o C

- Biopolymers, e. g. hyaluronic acid at 25oC

- Lubricants at 40oC and 100oC

- Marine Fuel Oils at 50oC

FAQ

You asked, we answered

Why are there so many different types of capillary viscometers?

Some viscometers are suitable for a specific purpose. In other cases, it is simply a question of industry tradition in different parts of the world. In the US, the laboratories often favour viscometers of the Cannon-Fenske design, where the same sample could be measured in a Ubbelohde Viscometer in another part of the world.

Why are glass viscometers still so important ?

Many product specifications include data on kinematic viscosity and specify that this must be measured in compliance with a capillary viscosity test protocol. This method is also extremely accurate by comparison to other technologies.

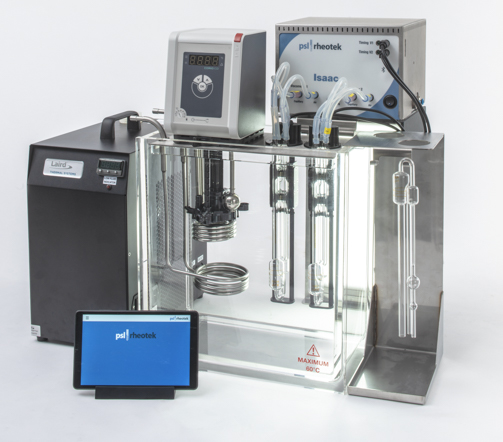

Do you offer instrumentation, which will automate the method protocol ?

At PSL Rheotek we have a wide range of automated instruments, which will automate every step of the measurement protocol as described in the method documents. Our automated instruments can easily be adapted and customised to suit individual requirements.

CUSTOM SOLUTIONS

Do you need a custom product for your custom requirements?

We listen to customer challenges. Each PSL Rheotek viscometer system is configured for the owner. A wide variety of international test method protocols are readily available in the software. Company specific method protocols are also supported.