CATEGORY BENEFITS

Automation with full method compliance

ASTM D2857, ISO 1628 parts 1, 2, 3, 4 & 5, ASTM D4603, ISO 307, ISO 5351, ASTM D4243, IEC 60450. If the protocol requires the use of a glass capillary viscometer in a constant temperature viscometer bath, the PSL Rheotek RPV can handle it. Superb repeatability with automated flow time detection. Temperature stability to +/- 0.01 degrees C. Fully automated cleaning and drying.

Step by step how to use it

The operator loads the sample, closes the cap and then presses “start testing” in the software. The following operations will then be conducted automatically: Sample elevation, sample resting, sample release, flow time determination in duplicate or triplicate as per method requirement, results calculation, sample removal, sample path cleaning, sample path drying. After approximately 26-30 minutes, the unit is then ready to accept a new sample.

PA, PET, PVC and many more

Automated viscometers are available in a wide range of configurations to suit client requirements. All our automated units feature a two or three solvent cleaning and drying system. This ensures, that the entire sample path is thoroughly cleaned and dried between each sample. Our applications experts will assist in setting the test parameters according to your specifications

Operator safety

Cleaning and drying of the sample path is fully automated. Operator contact with solvents is limited to refilling tanks and emptying waste containers. Using an automated polymer viscometer makes solvent based viscosity easy and safe.

Method compliance

ASTM D4603, ISO 1628 parts 1 to 5, ISO 5351, ASTM D789, TAPPI T230, ASTM D1243, ASTM D4243, IEC 60450 and many more protocols readily available as off-the shelf software configurations. Custom protocols designed to order.

Certificate of Analysis Testing

The PSL Rheotek Polymer Viscometer provides the data for batch release certificate of analysis testing. Process plants across the world place their trust in the RPV polymer viscometer. Automated polymer viscosity measurement with full method compliance.

rPET can also be measured

Recycled polymers present a challenge in many processes. Solvent based viscosity provides the real data on polymer properties for extruders, blow moulders, injection moulders, compounders and trading houses. The PSL Rheotek Polymer Viscometer can handle samples with glass fibre & additives.

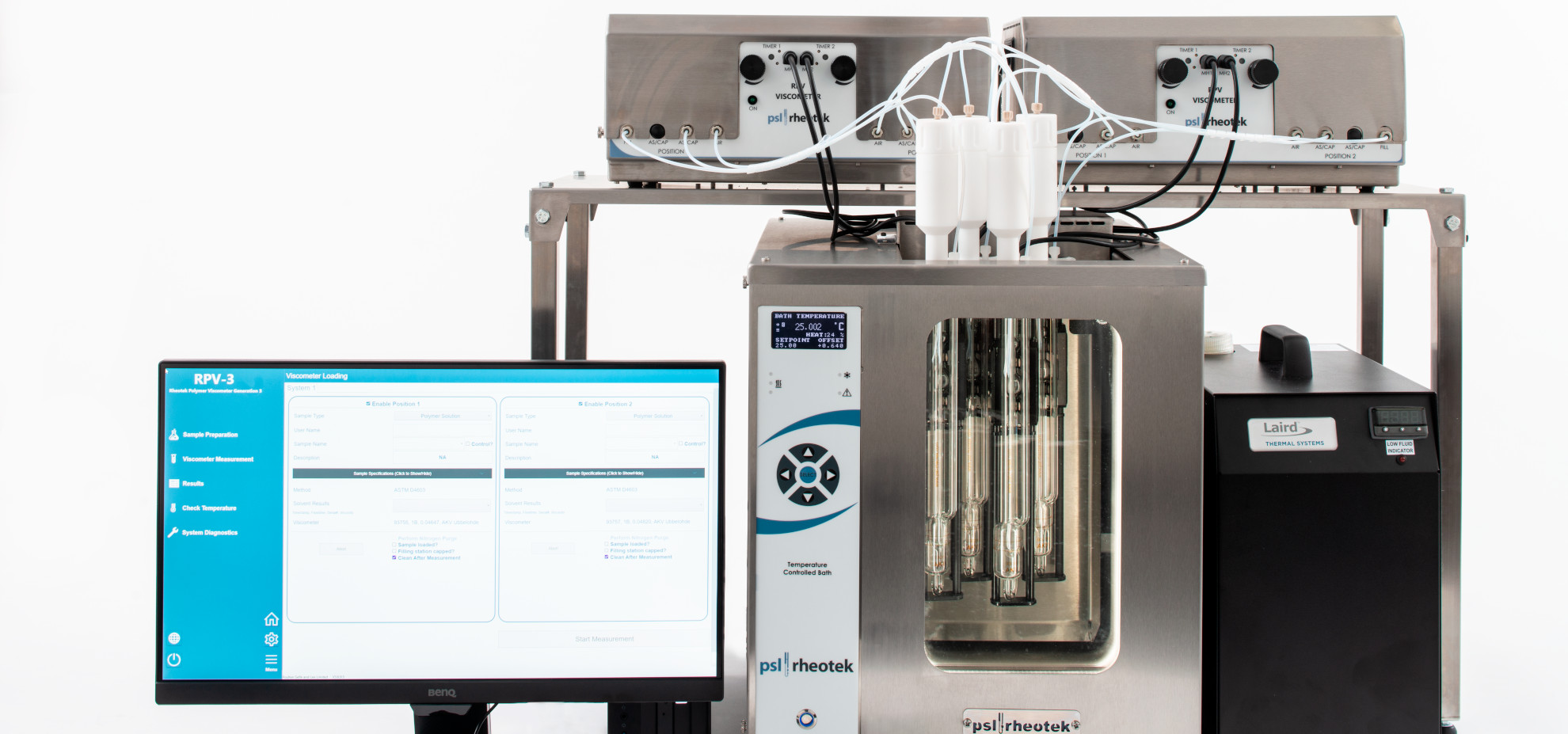

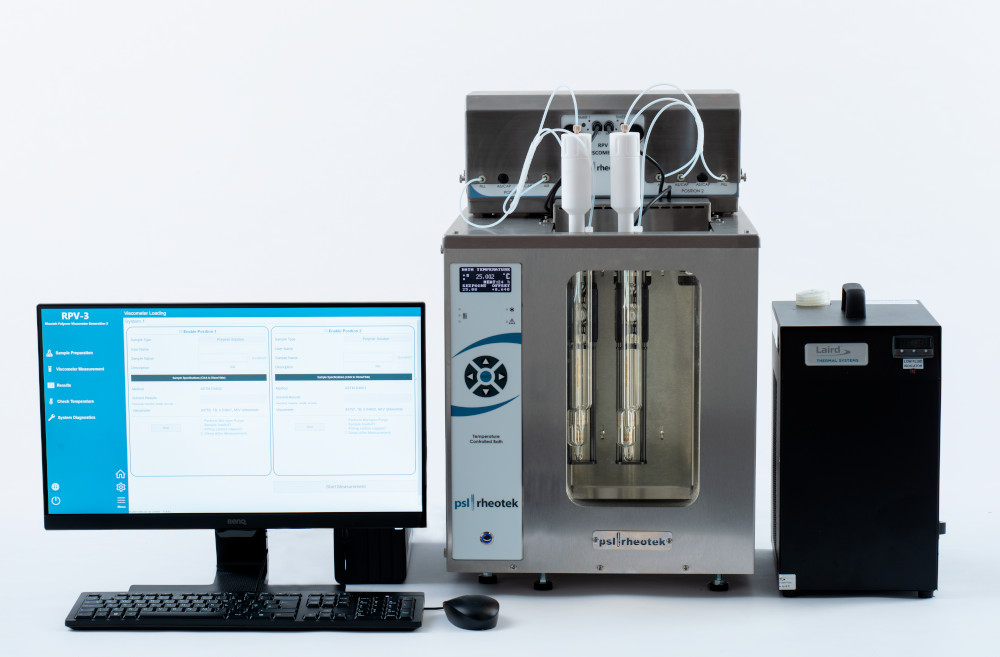

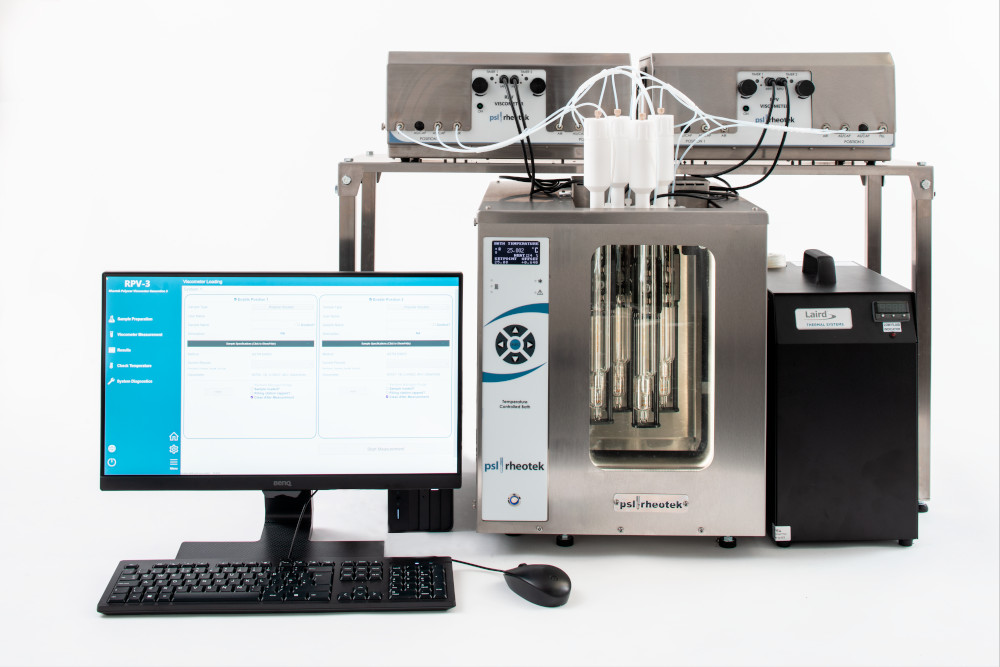

PRODUCT GALLERY

Automated Polymer Viscometers

NEW GENERATION | RPV-3 OUT NOW

Tried and tested detection technology in modern packaging

A fresh approach to electronics and software has produced the third generation of PSL Rheotek Polymer Viscometers. Available now to industry users, who look to the future. Developed, designed and manufactured in the UK.

DOWNLOAD

FAQ

You asked, we answered

Is this really reliable?

An automated viscometer conducts a physical properties test and has solvent and sample going through tubes and valves. Periodical maintenance is essential. Our Technical Service Team is on hand to assist either on a case-by-case basis or on a contract basis.

How much does it cost?

The price will depend on the scope of delivery relevant for the specific project. Please get in touch to arrange an on-line consultation with a team member for an initial discussion and some ball park pricing.

We test KV of mineral oil at 40 degrees C in our lab, can your unit do this?

Certainly, please get in touch for a consultation with one of our team members to discuss the type of sample you have and the viscosity ranges in question.

We need to test IV of PET on regrind and rPET. Can you help us?

We will be delighted to offer our complete starter kit for this test and provide advice on recommended laboratory installation. Please get in touch to arrange an on-line consultation with one of our team members to discuss.

Do you offer training in Polymer Viscosity?

Attention to detail is crucial in polymer viscosity. Our applications specialists will be pleased to conduct individually tailored training to lab staff from client sites. Use the contact form to enquire about training.