CATEGORY BENEFITS

Quality Assurance in the laboratory with PSL-Rheotek viscosity oil standards

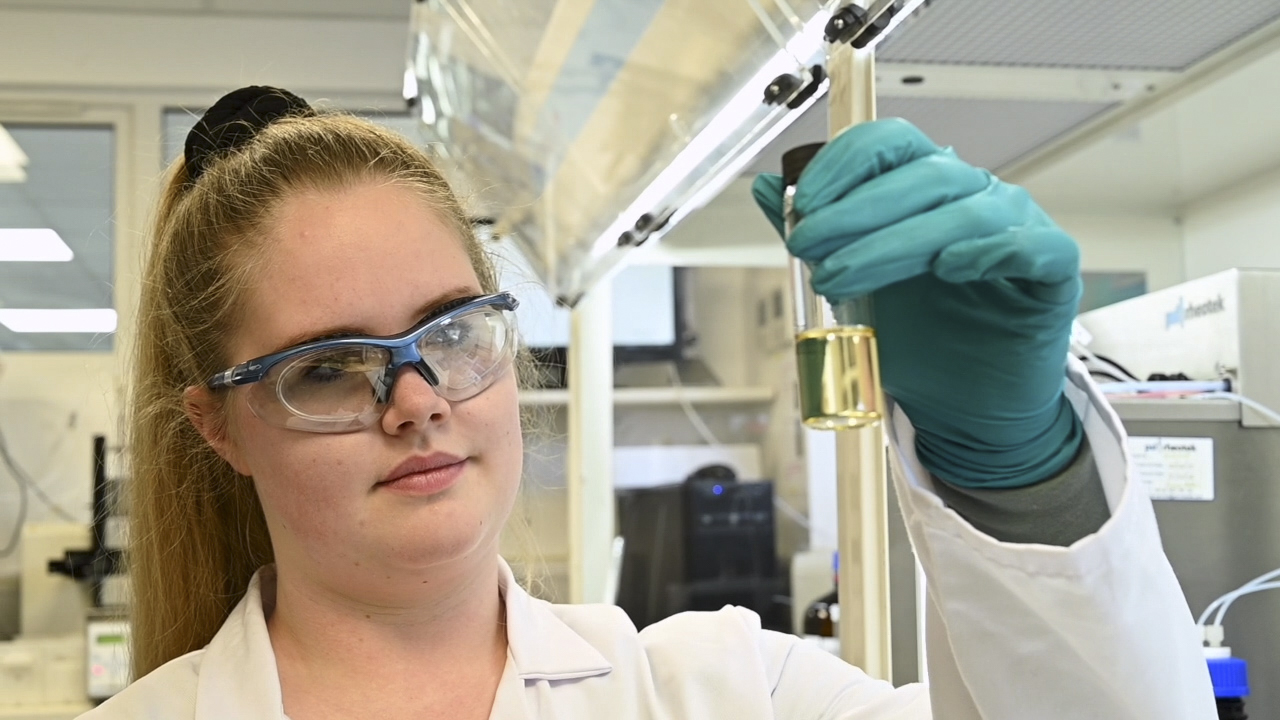

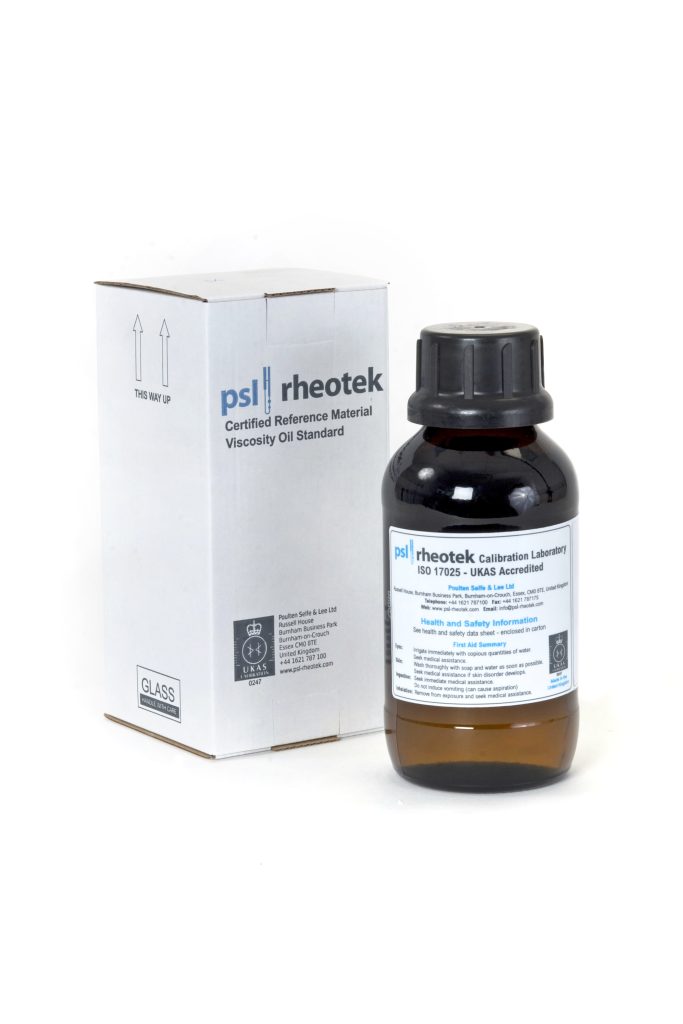

A viscosity standard is a bottle of mineral oil with certified values in viscosity and density. When you run an oil viscosity standard, you know exactly which result you are looking for. The quality manual will specify how often the viscometers need to be validated. If your results are outside of tolerance, you will need to replace the viscometer or send it in for recalibration. When using a glass viscometer, it is good practice to use oil viscosity standards to check that you are getting the right numbers. This validation is good practice for ongoing quality assurance.

Comparing your result to the certified values on the bottle will give you the information needed to pass an upcoming audit. In between audits, the verification with an oil viscosity standard provides peace of mind.

Why choose PSL-Rheotek viscosity standards?

The PSL Calibration Laboratory is accredited to ISO 17025 for calibration work in viscosity and temperature by UKAS (United Kingdom Accreditation Service), Lab No 0247. The PSL Calibration Laboratory maintains a master viscometer scale calibrated to ASTM D2162. Manufacturing and handling of reference materials is certified under ISO 17034, Lab No 5076. Calibrations performed include the measurement of Viscosity Reference Standards in the temperature range -40 to 135 deg. C.

How to find the right viscosity standard

The most reliable verification is obtained by choosing an oil viscosity standard with a nominal value close to your production samples. Check out this link for a table of standards and values.

PSL Viscosity Reference Standards are suitable for the verification and calibration of glass capillary viscometers, flow cups, rotational viscometers & Cone and Plate viscometers. Oil viscosity standards cover the entire viscosity range. For instructions on how to conduct the calibration, please refer to the procedure in ASTM D445 or ISO 3104.

Certified values are provided for kinematic viscosity, dynamic viscosity and density, together with uncertainties of measurement to consider, when you use viscosity standards to check. The uncertainty evaluation has been carried out in accordance with requirements specified by the United Kingdom Accreditation Service (UKAS). The following types of oil viscosity standards are available in the PSL Rheotek range:

- kinematic viscosity

- low temperature

- high viscosity

- dynamic viscosity

Tip

The most reliable verification of your work is achieved, when you use a viscosity standard that has a similar viscosity value as your production samples. For example, if your production sample is a diesel oil, which usually comes in at 2.7 mm2/s at 40 degrees C, the optimal viscosity reference standard is the S3. This has a nominal value of 3 mm2/s at 40 degrees C.

How to read the results

It is very unlikely that your result will be 100% identical to the certified value on the bottle of the viscosity standard. The quality manual in your laboratory will provide the data on the allowed tolerance band. If there is no tolerance band for verification with viscosity standards in your laboratory quality manual, you can refer to the acceptable tolerance bands listed in Annex A4 of the method document ASTM D445.

If your result is inside the tolerance band, all is good and you can be sure that you have completed the verification using a viscosity standard.

If your result is outside the tolerance band, the first thing to do is to run the viscosity standard again. The purpose of this is to establish whether the first result of the viscosity standard test was an outlier. If the next measurement of the viscosity standard is also outside the tolerance band, you can send the viscometer to us for recalibration or buy a new viscometer in our Webshop.

FAQ

You asked, we answered

What is the shelf life of an oil viscosity standard?

Two years from date of shipping.

How do I store my viscosity standards?

We recommend storing the viscosity standards away from direct sunlight at a cool and stable temperature. 20 degrees C or 60 degrees F is ideal.

Can I reuse the oil viscosity standard?

No, this is not possible. On completion of verification, the portion of the bottle used for the testing must be discarded. Oil viscosity standards are single use.

What is the traceability of the certificate of calibration?

Our laboratory is UKAS accredited and audited every year. Our work in viscosity calibration, production of reference materials and handling of reference materials is carried out under ISO 17025 and ISO 17034. Sample certificates of calibration are available on request.

What is the primary reference in kinematic viscosity?

The primary reference in kinematic viscosity is double distilled water at 20 degrees C. This has an internationally agreed viscosity of 1.0034 cSt or mm2/second.

CUSTOM SOLUTIONS

Do you need a custom product for your custom requirements?

We listen to customer challenges. Each PSL Rheotek viscometer system is configured for the owner. A wide variety of international test method protocols are readily available in the software. Company specific method protocols are also supported.